The Importance of Voltage Regulators

Voltage Regulators

A voltage regulator is like the cruise control in a car for electric utilities; it is an electronic device that automatically maintains a consistent voltage level. Regulators raise and lower the voltage to a desired level. When voltage regulators stop working, the voltage can reach levels that cause equipment damage and safety hazards.

Voltage regulators are workhorses that operate 1000's of times a year to maintain voltage. Because of their importance, electric utilities should inspect regulators monthly. Continuous inspection and scheduled maintenance are critical.

Inspectors should check the voltage regulator's overall condition, document any deficiencies, document the high and low drag hands positions, and document the operation counter.

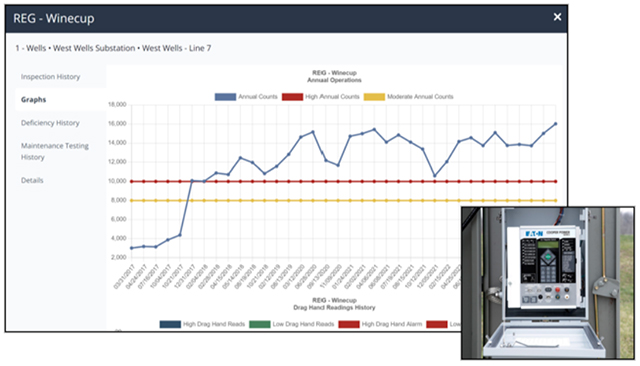

A good program will assess deficiencies for their risk to the system and instantly analyze drag hand positions and operation counters. In addition, a good program will watch for alarm points and disturbing trends.

Operation Counters

Track and trend your operation counters — don't just write them down!

Each time a voltage regulator operates, copper contacts slide across each other, changing the winding ratio and raising and lowering voltage as required. As these contacts slide over time, they can rut, pit, and contaminate, building resistance. This resistance will lead to heat, failure, and possible explosion.

Typically, regulators and LTC's can operate 100,000 times or 10 years before needing maintenance. Track and trend your operation counts to ensure everyone goes home safe, extend equipment lifespan, and reduce maintenance expenses.

Drag Hands

Track and trend your drag hands — don't just write them down!

A voltage regulator can raise or lower voltage up to 10%. The drag hands let you know high and how your system voltage varies over time. Tracking voltage levels throughout the system gives you peace of mind that you deliver a good product.

In addition, voltage regulator drag hands identify overloaded feeders and allow for proper capacitor placement. Finally, you can better allocate and save on capital and maintenance budgets.

Overall Condition — Inspect with a purpose

Looking for and documenting deficiencies is critical to great inspection software. But if you want your inspection program to be effective, you should assess the risk of each defect.

Risk assessment of a deficiency considers both the chance of failure and the consequence of failure. A "Find, Assess, and Fix" inspection program will continuously improve the electrical system. If you have an "inspect and forget" inspection program, it is time to turn to PZM's Inspection Software.

PZM instantly tracks and trends all drag hands and operation counters on voltage regulators and all other critical equipment in the substation. PZM uses Protection Zones and Risk Matrixes to perform a risk assessment on all deficiencies.

About Protection Zone Management—PZM

Cooperatives and Utilities are turning to PZM's substation inspection program. PZM has revolutionized how electrical equipment is inspected and maintained.

Our software uses sophisticated algorithms to track and trend data, providing valuable insights into the behavior of voltage regulators and all other critical substation equipment.

Benefits of PZM include:

- Detailed, electrical industry specific inspection questions.

- Eliminates paper-based dual data collection.

- Instant deficiency identification and assessment.

- PZM syncs the information to the cloud where it can be accessed from your office, your home, or on the road.

- Instant access to all of your electric utility data.

PZM is an electrical utilities inspection software solution that puts your inspection and maintenance program on cruise control and frees up management time for other important business initiatives.